11 Tips for Managing Quality Control in Tin Soldering with Induction Heating

Qualified inspectors play a critical role in ensuring the quality and reliability of tin soldering jobs, especially when using induction heating or other methods.

Qualified inspectors play a critical role in ensuring the quality and reliability of tin soldering jobs, especially when using induction heating or other methods.

Let’s define a few terms before diving into this topic.

Brazing and Soldering are both metal-joining processes that you’d encounter in manufacturing facilities of all stripes. The core difference lies in the temperature that this process demands, as well as the alloy utilized as a filler metal.

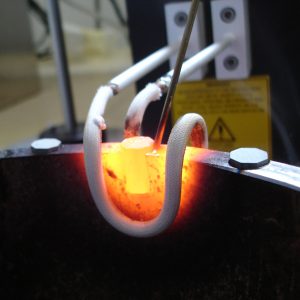

Both can be done via induction heating with great efficiency.

So, what sort of best practices should those manufacturers keep in mind when developing SOPs around their soldering work? Let’s take tin alloy soldering as an example, and let’s consider what sort of factors a qualified inspector might scout on-site.

When scrutinizing a tin soldering job, inspectors typically look for several key factors to determine whether the work meets acceptable standards. It may help to think like an inspector, even to look around your team’s workspace with the eyes of an inspector, to guarantee an efficient job. Your team will want to stay on top of those factors, which include:

Visual Inspection

Visual inspection involves a thorough examination of the soldered joint, checking for proper wetting to ensure the solder has formed a uniform bond.

The inspector evaluates the fillet size and shape, looking for any visual defects such as voids, cracks, or excess solder that could impact the joint’s integrity. This meticulous examination is crucial for identifying potential weaknesses or irregularities that might compromise the overall quality of the joint. Manufacturers can facilitate visual inspections by implementing well-lit workstations and using magnification tools, such as microscopes, to enhance the inspector’s ability to identify minute details in the joint.

WANT TO LEARN MORE ABOUT BRAZING AND SOLDERING? GET IN TOUCH TODAY

Solder Material

Inspectors confirm that the correct solder alloy and flux have been used, ensuring they match the specifications for the particular application.

Additionally, they may assess the solder’s condition, checking for proper storage and shelf life to maintain its effectiveness during the soldering process. The choice of the right solder material is fundamental to achieving a reliable and durable joint, and inspectors pay close attention to material compatibility and quality. Manufacturers can ensure compliance by implementing strict material handling procedures, maintaining clear labeling, and regularly auditing material stocks to prevent the use of outdated or incorrect solder.

Temperature Profile

Inspectors ensure that the induction heating process or other heating methods achieve the precise temperatures required for effective soldering without compromising the structural integrity of the materials being joined.

This involves not only monitoring the peak temperatures but also assessing the ramp-up and cool-down phases to guarantee a controlled and consistent thermal process. Manufacturers can achieve this by implementing calibrated temperature control systems, conducting regular equipment maintenance, and providing adequate training for operators to follow prescribed heating profiles accurately.

Cleanliness

Cleanliness involves more than just surface preparation.

Inspectors check for any contaminants or oxides that might hinder the solder’s adherence. They also assess the effectiveness of the cleaning process post-soldering, as residual flux can affect the joint’s long-term reliability. Maintaining a clean working environment is essential for preventing impurities that could compromise the integrity of the soldered joint over time. Manufacturers can enforce stringent cleanliness protocols by implementing proper storage and handling of materials, using effective cleaning agents, and regularly auditing the cleanliness of workstations and equipment.

Lead-Free Compliance

For applications requiring lead-free soldering, inspectors verify compliance with environmental regulations and industry standards.

They ensure that the soldering process aligns with the specifications for materials that are free of lead and other restricted substances. Adhering to lead-free requirements is not only a regulatory necessity but also contributes to environmentally friendly and sustainable manufacturing practices. Manufacturers can achieve lead-free compliance by sourcing and clearly labeling lead-free materials, providing training on lead-free soldering techniques, and regularly auditing processes to ensure ongoing compliance.

Mechanical Strength

The mechanical strength of the soldered joint is a critical consideration. Inspectors assess whether the joint can withstand the intended mechanical stresses and loads without compromising the overall structural integrity of the components.

This evaluation includes considerations of joint geometry, filler metal penetration, and the overall robustness required for the specific application. Manufacturers can optimize mechanical strength by carefully selecting solder alloys and joint designs, implementing standardized joint preparation procedures, and conducting mechanical testing to validate joint strength under representative conditions.

Electrical and Thermal Performance

Beyond the visual appearance, inspectors test the electrical conductivity and thermal performance of the soldered connections.

This includes checking for proper electrical continuity and insulation resistance where applicable, ensuring the joint meets the necessary performance criteria. Evaluating electrical and thermal characteristics is essential, particularly in applications where these properties directly influence the functionality and reliability of the soldered assembly. Manufacturers can conduct rigorous electrical and thermal testing, implement quality control measures for consistent soldering practices, and invest in advanced testing equipment to assess performance accurately.

Soldering Process Documentation

Reviewing process documentation involves scrutinizing temperature profiles, soldering parameters, and work instructions.

Inspectors ensure that the soldering process adheres to established standards, helping to maintain consistency and traceability in production. Comprehensive documentation not only facilitates effective inspection but also forms the basis for process improvement and optimization. Manufacturers can accomplish this by implementing robust documentation systems, regularly updating procedures based on lessons learned, and providing training to ensure operators follow standardized processes.

Consistency and Reproducibility

Inspectors assess whether the soldering process can consistently produce soldered joints with repeatable quality. Consistency and reproducibility are vital for manufacturing processes, as variations can impact the overall quality and reliability of the final product.

Ensuring that the soldering process is reliable and repeatable contributes to a more efficient and predictable manufacturing operation. Manufacturers can achieve consistency by implementing standardized operating procedures, conducting regular training programs, and utilizing process control techniques such as Statistical Process Control (SPC) to monitor and maintain consistent soldering parameters.

Defect Analysis

In the event of defects, inspectors conduct a thorough analysis to identify the root causes. This involves not only identifying the visible defects but also understanding the underlying factors that contributed to their occurrence, allowing for corrective actions to be implemented.

Root cause analysis is a crucial step in continuous improvement, as it enables the identification and elimination of systemic issues in the soldering process. Manufacturers can foster a culture of continuous improvement by encouraging open communication, conducting regular defect analysis meetings, and implementing corrective and preventive actions based on the findings.

Compliance with Standards

Inspectors ensure that the soldering job aligns with relevant industry standards and specifications. Compliance is crucial for meeting safety, quality, and regulatory requirements, ensuring that the final product meets or exceeds the expected standards.

Adhering to standards not only ensures the quality of individual soldered joints but also contributes to the overall reliability and safety of the products being manufactured. Manufacturers can accomplish this by staying informed about industry standards, regularly updating procedures to align with evolving standards, and conducting internal and external audits to verify compliance.

Qualified inspectors follow specific inspection procedures and use various inspection tools and equipment, such as microscopes, magnifiers, continuity testers, and solderability testing equipment, to evaluate these factors. Their goal is to ensure that soldered joints are reliable, durable, and meet the requirements of the intended application.

WANT TO LEARN MORE ABOUT BRAZING AND SOLDERING? GET IN TOUCH TODAY