Controllers, Pyrometers & Accessories

Home » CEIA Controllers, Pyrometers & Accessories

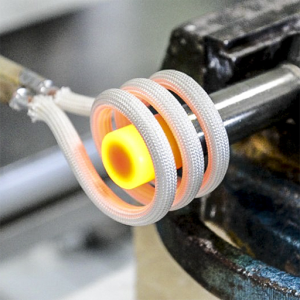

- Induction Heating Equipment

CEIA Controllers, Pyrometers & Accessories

The Master Controller V3+ is a multifunction industrial control unit, designed for automatic management of programmable eating processes.

All operating parameters for each phase of the heating cycle can be programmed within a wide range of values.

- Master Controller v3+

- Master Controller v3+ Accessories

- CEIA Optical Pyrometers

- CEIA Pyrometers Accessories

Master Controller v3+

Multifunction Heating Process Controller

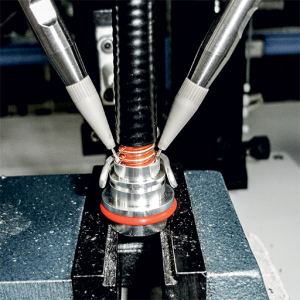

- Programming and management of up to two independent heating stations, consisting of: CEIA Power Cube Generator; CEIA SH/SLE series non-contact temperature sensor or external thermocouples; automatic solder dispenser; antioxidant gas diffuser

- High-definition graphic display

- Internal memory and removable SDC Card containing up to 100 work programs

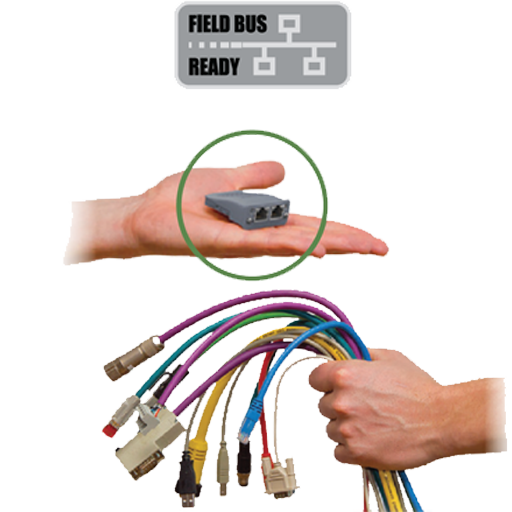

- Multiple interface Capability including: Industrial current/voltage I/O; Field Bus; RS-232; up to 22 input and 22 output

- Validation and Reporting of each heating cycle for Production Quality Control and Certification

- “STATUS” key for immediate reading of main Generator working parameters

- “QUICK ACCESS” key for fast programming of user defined parameters

- Alternating between the two heads (if connected to a single Power Cube generator)

- Simultaneously on two heads (if connected to two Power Cube generators)

- Capable of driving Power Cube generators in continuous operation

- Activation of cycle: via external contact, RS-232 or Fieldbus interface

- Control and Time Programming of 2 antioxidant gas diffusers, 2 heating heads and 2 wire dispensers

- Available Settings: heating power; heating temperature (resolution 0,1°C); wire quantity and speed; antioxidant gas supply times; maximum solder force; wire feeder; piston advance delay

- Control of the temperature of the article being processed: via optical temperature sensors, thermocouple or external sensors

- SH15/SLE sample rate: 0.5 milliseconds

- SH15/SLE time constant: 0.1 milliseconds

Master Controller v3+

Accessories

Field Bus Management

| Integrated Web server and Data Log System

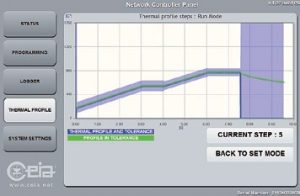

The Master Controller V3+ has an integrated Data Log and Web Server system. It is possible to perform automatic data storage for proper process quality control, monitoring heating temperatures, output power, frequency, voltage, and inductor current. An Ethernet TCP/IP port allows access to the internal web server of the Master Controller for remote programming settings and interface with SCADA / DCS systems.

| Thermal Profile Management and Monitoring

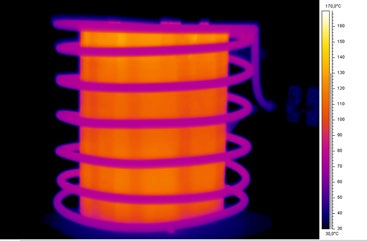

Thermocamera Control

|

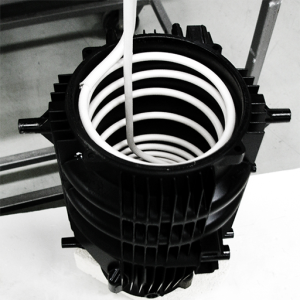

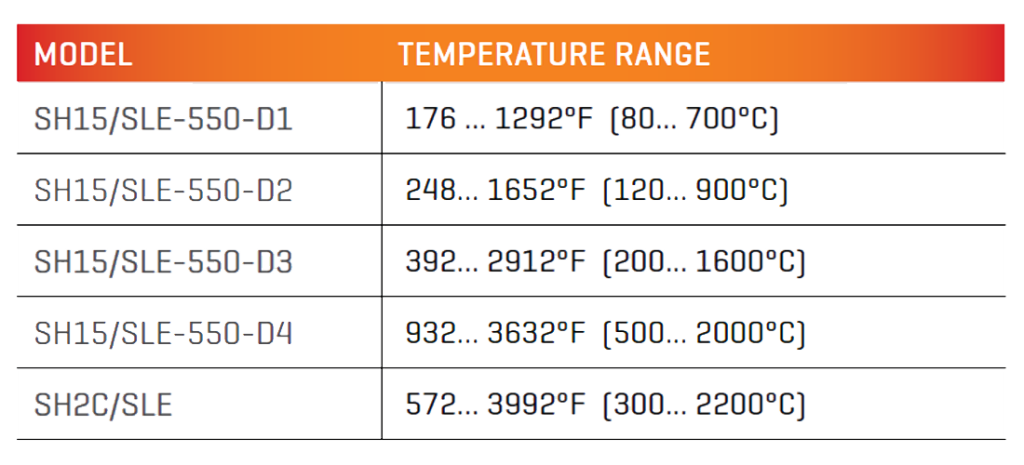

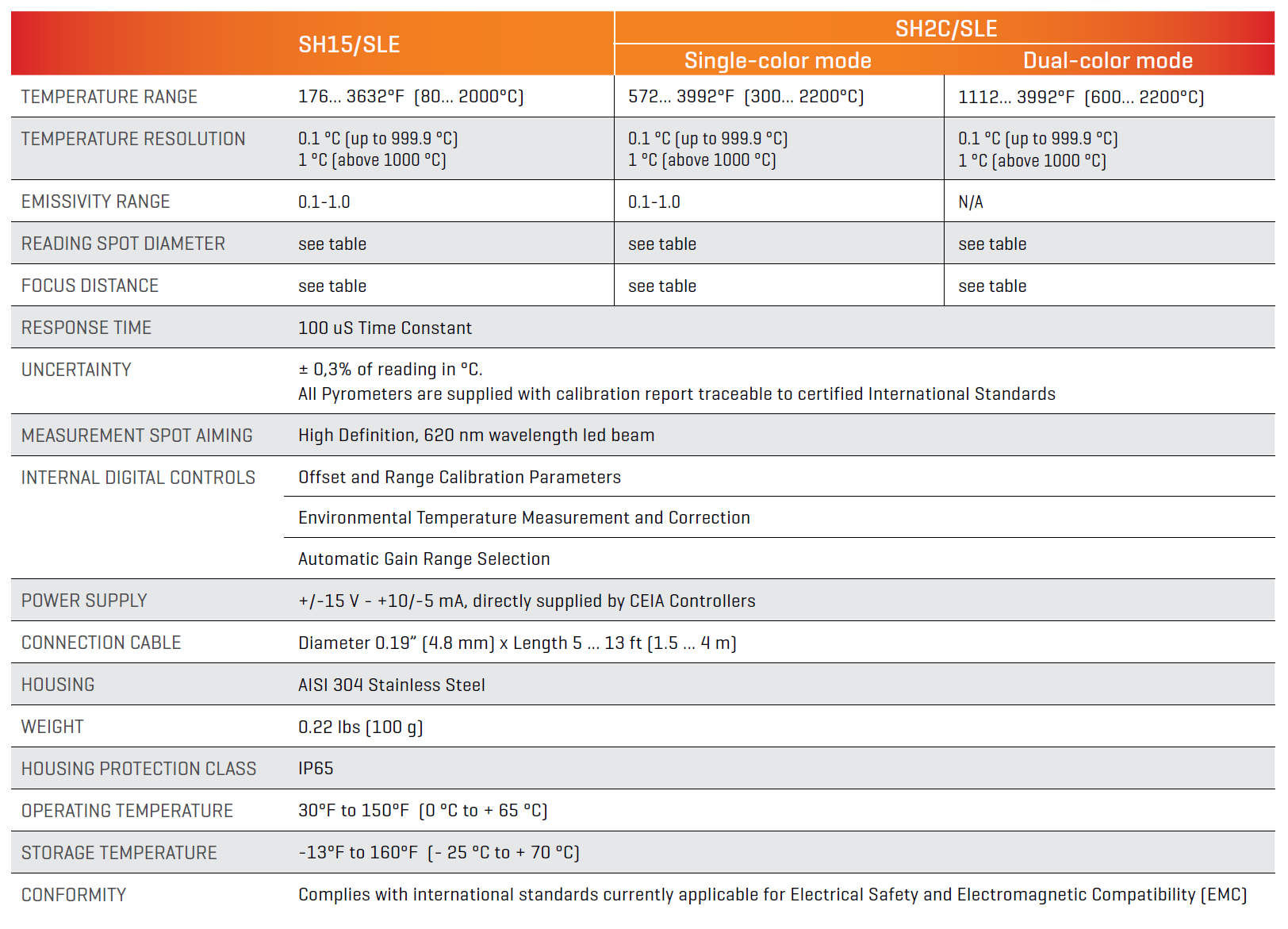

SH/SLE Compact Optical Pyrometers

Single and Dual-Color

|

|

CEIA SH2C/SLE

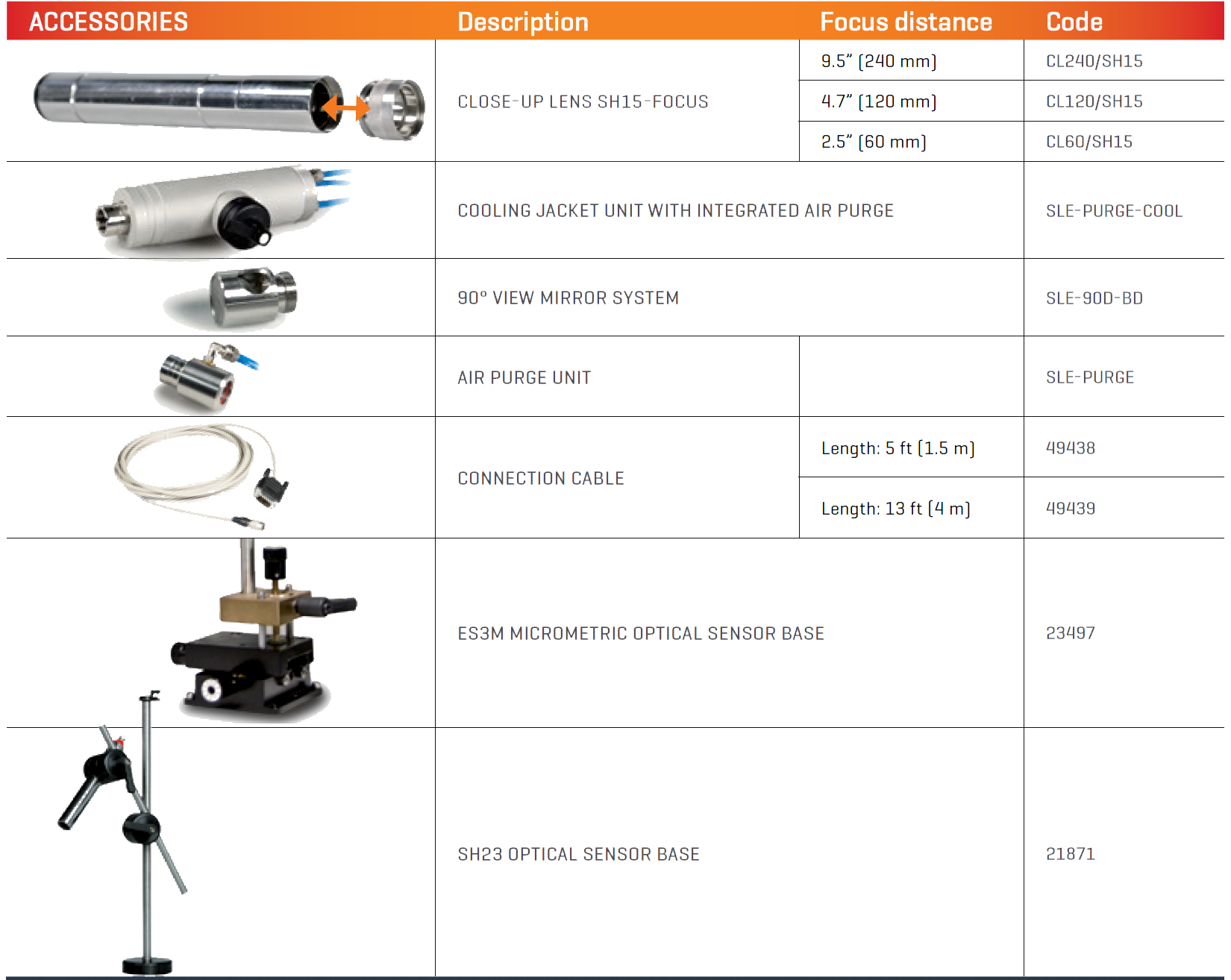

Accessories