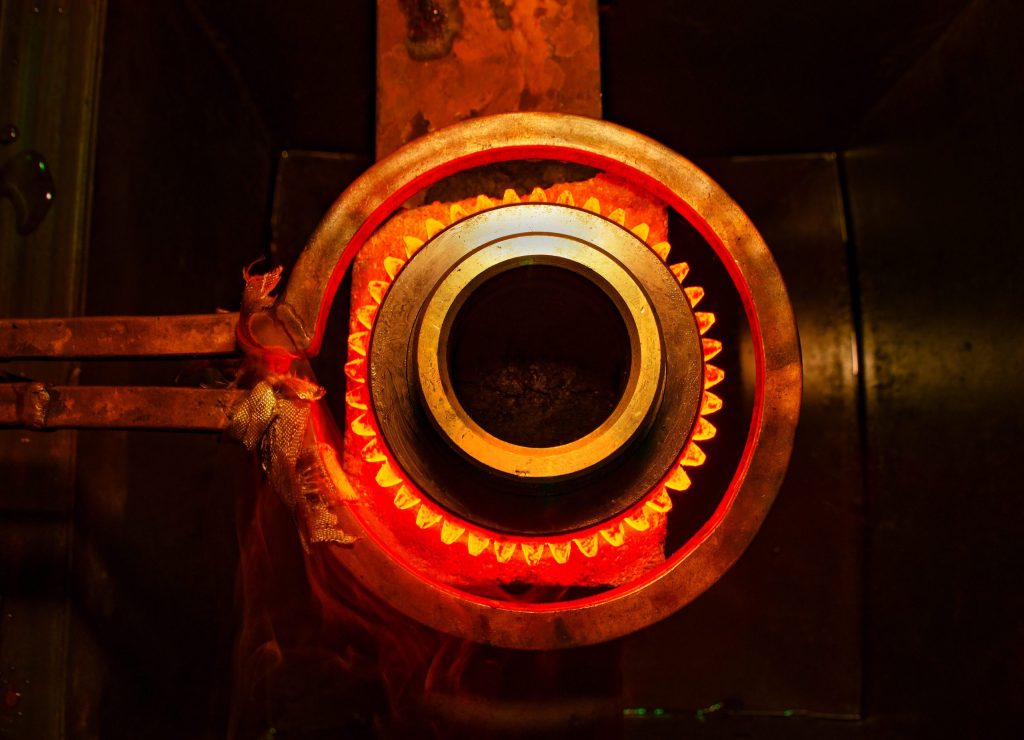

Design the Coil Right: Shape, Turns, and Gap That Deliver

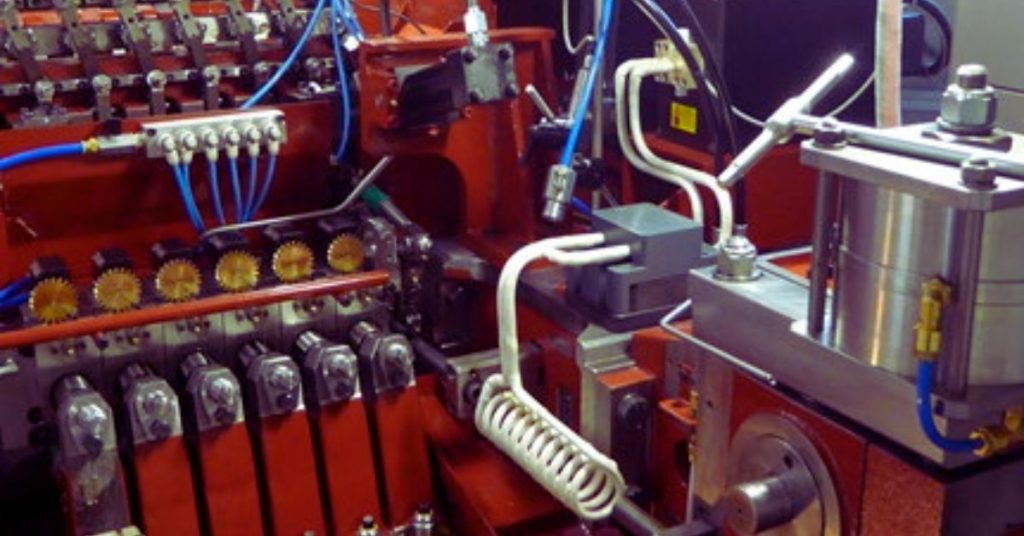

The coil is your tooling for heat. When it matches the part and the job, you get fast, even, repeatable results. When it doesn’t, you fight hot spots, slow cycles, and drift. Use this as a practical guide to pick and tune a coil that works on the floor, not just on paper. Start With […]

Design the Coil Right: Shape, Turns, and Gap That Deliver Read More »