Best Practices for Curing Different Manufacturing Materials

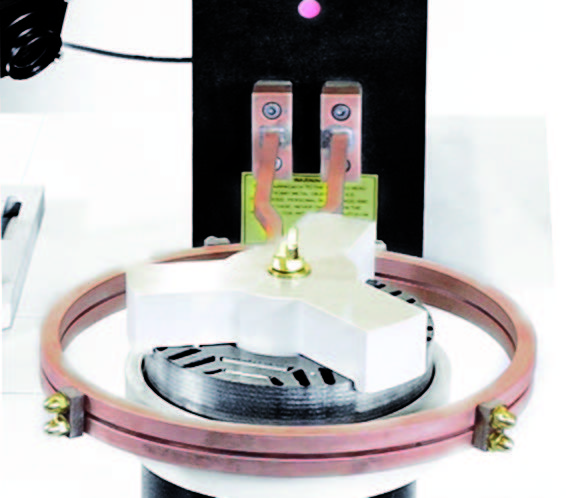

In manufacturing settings, the curing process is pivotal in determining the final properties of materials, ensuring that the finished product will be able to withstand the stresses and strains it will be subjected to in its intended use. Induction heating offers an efficient medium for getting your work done at scale.

In manufacturing settings, the curing process is pivotal in determining the final properties of materials, ensuring that the finished product will be able to withstand the stresses and strains it will be subjected to in its intended use. Induction heating offers an efficient medium for getting your work done at scale.

The effectiveness of induction heating varies with the electromagnetic and thermal properties of different metals; ferrous alloys respond more efficiently than non-ferrous materials, for example.

Optimal curing in a manufacturing context requires fine-tuning of induction parameters such as coil design, alternating current frequency, and specific heat treatment cycles.

Metals and alloys undergo thermal treatments like annealing and tempering, aimed at microstructural modification to enhance mechanical properties.

For polymers and composites, by contrast, this work involves thermoset cross-linking (covalent bonds joining polymer chains), which induces a state change to achieve a desired structural integrity.

The challenge is achieving the precise degree of cross-linking for thermosetting polymers, crucial for mechanical strength and thermal stability. In composites, discrepancies in thermal expansion demand a carefully engineered curing cycle, balancing ramp-up rate, peak temperature, and controlled cooling.

One concept we’ll return to throughout this article: Uniformity in your induction heating process is key to the cure.

Let’s take a closer look at the properties of some of these materials and how they may be influenced by induction heating.

Metals and Alloys

Metals and alloys are characterized by high thermal conductivity and varying degrees of electrical conductivity. Their microstructures can be altered through heating, affecting mechanical properties like hardness, ductility, and tensile strength.

When it comes to curing metals and alloys, you must ensure uniform heating across the material. You need to avoid thermal gradients that can lead to uneven curing or material stress. After heating, control the cooling rate. Like we said, uniformity is key.

For example, in steel, controlled cooling after induction heating can change the crystal structure, resulting in different types of steel with varied properties. The specific heat treatment (annealing, quenching, tempering) depends on the desired microstructural changes.

Polymers and Composites

These materials are made of long-chain molecules and can range from soft and flexible to hard and rigid. Composites combine polymers with reinforcements like fibers, and their properties depend on both the matrix and the reinforcement. Follow the recommended temperature profile precisely, as polymers and composites can be sensitive to temperature variations. Excessive heat can lead to an incomplete curing job or even degradation of your material. (Note that some polymers release fumes when heated, requiring good ventilation.)

In some cases, applying pressure during curing can help in achieving desired material properties.

Adhesives and Bonding Agents

These are typically polymers with varying viscosities and chemical compositions (think liquid or paste), designed to bond surfaces through a curing process that solidifies the adhesive. This curing work will often take place in the automotive or electronic sectors, where materials must be joined together.

Adhesives often require specific temperatures for effective curing. Maintain these temperatures accurately and avoid overheating the material. Overheating can degrade the adhesive and reduce its bonding strength.

Ceramics and Glass

These are brittle materials with low thermal conductivity and high melting points. They are often thermally and chemically stable, and they typically require slow heating and cooling to prevent cracking due to thermal shock.

Controlled cooling is equally important to avoid introducing residual stresses. The curing process often requires maintaining temperatures below the melting point while still achieving the necessary phase changes.

In some cases, controlling the atmosphere (like inert gas environments) during curing can improve material properties.

Paints and Coatings

Composed of pigments, resins, solvents, and additives, these materials have varying drying and curing mechanisms, often involving solvent evaporation and polymerization.

Ensure the surface is properly prepared and clean for effective curing. Maintain consistent coating thickness for uniform curing. Note that humidity and ambient temperature can affect the curing process.

Electronic Components

These often involve a combination of metals, polymers, and ceramics, each with distinct thermal and electrical properties.

Careful temperature management is crucial, as excessive heat can damage sensitive components. Curing processes must consider the thermal tolerance of each component to avoid degradation of electronic properties; many electronic components are sensitive to high temperatures. Use low-temperature curing processes.

General Reminders!

Documentation and Standardization: Document curing processes and maintain standardized procedures for consistency.

Regular Calibration: Regularly calibrate equipment to ensure accuracy.

Safety: Implement and adhere to safety protocols for handling high-temperature materials and equipment.

Quality Control: Establish robust quality control measures to ensure each batch meets the required standards.

Continuous Monitoring and Feedback: Use sensors and data logging for real-time monitoring and feedback for process adjustments.