HTS Blog

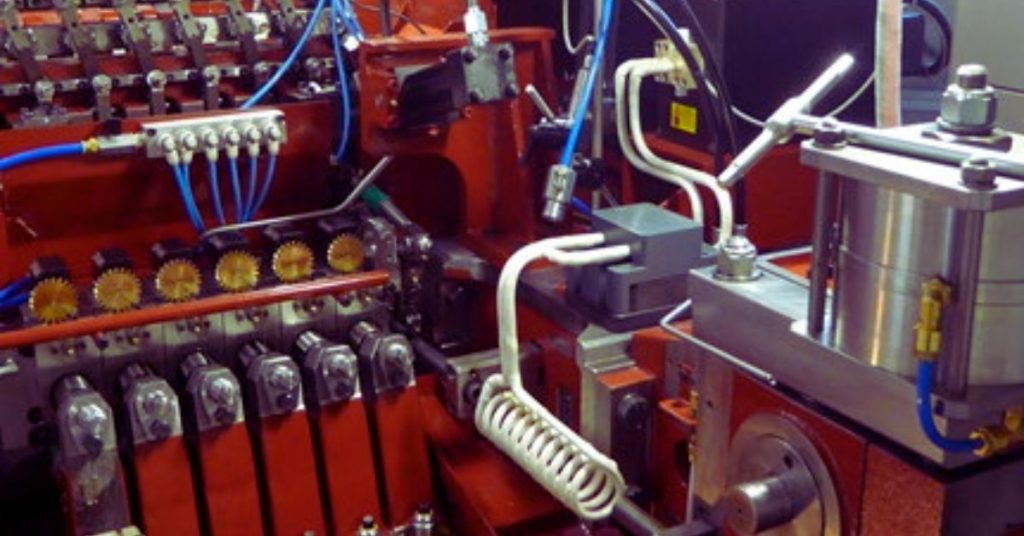

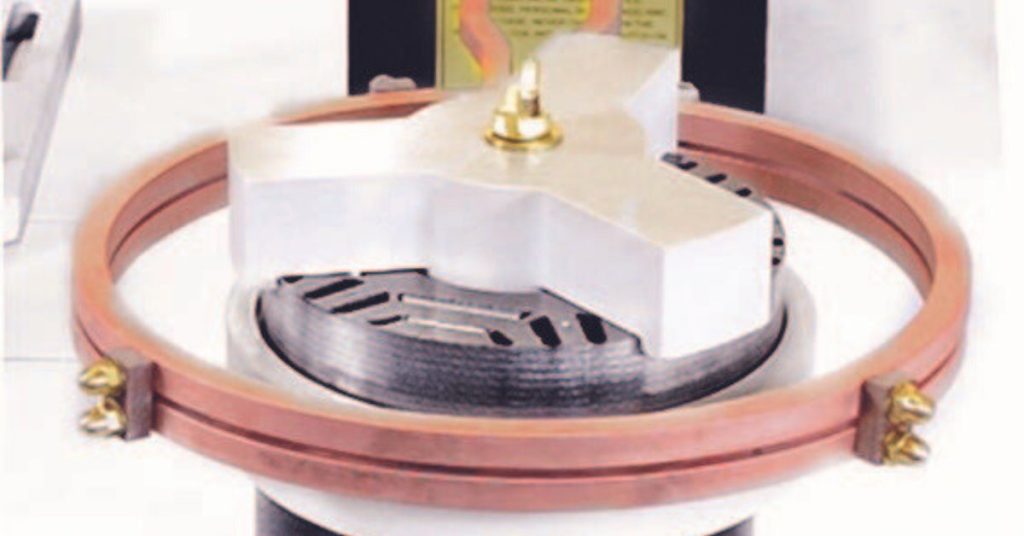

The coil is your tooling for heat. When it matches the part and the job, you get fast, even, repeatable results.

You know induction heating delivers fast, clean heat. The question isn’t “does it work,” it’s “is now the right time to bring it in?”

Now you need to turn your one-cell success into a repeatable process across shifts, plants, and product lines. That means a clear, enforceable Standard Operating Procedure (SOP).

A single induction station can cut hours from a furnace cycle, but the real payoff arrives when you roll that success across your plant.

Modern chillers stream inlet temperature, outlet temperature, flow, pressure, compressor current, fan speed, and even vibration.

If you don’t pull heat out quickly and consistently, coil temperature drifts, coupling efficiency drops, seals fail, and parts drift out of spec. A well‑chosen chiller fixes those problems.

Learn how induction heating slashes cycle times, saves energy, and delivers finer microstructures when forging and heat-treating nickel-based turbine blades.

By controlling how and where heat is applied, induction allows engineers to achieve carefully tailored hardness profiles while minimizing distortion and energy consumption.

Whether treating a fuselage panel, a turbine component, or a fastener interface, induction applies heat only where needed—preventing unnecessary thermal stress on delicate or heat-sensitive areas.

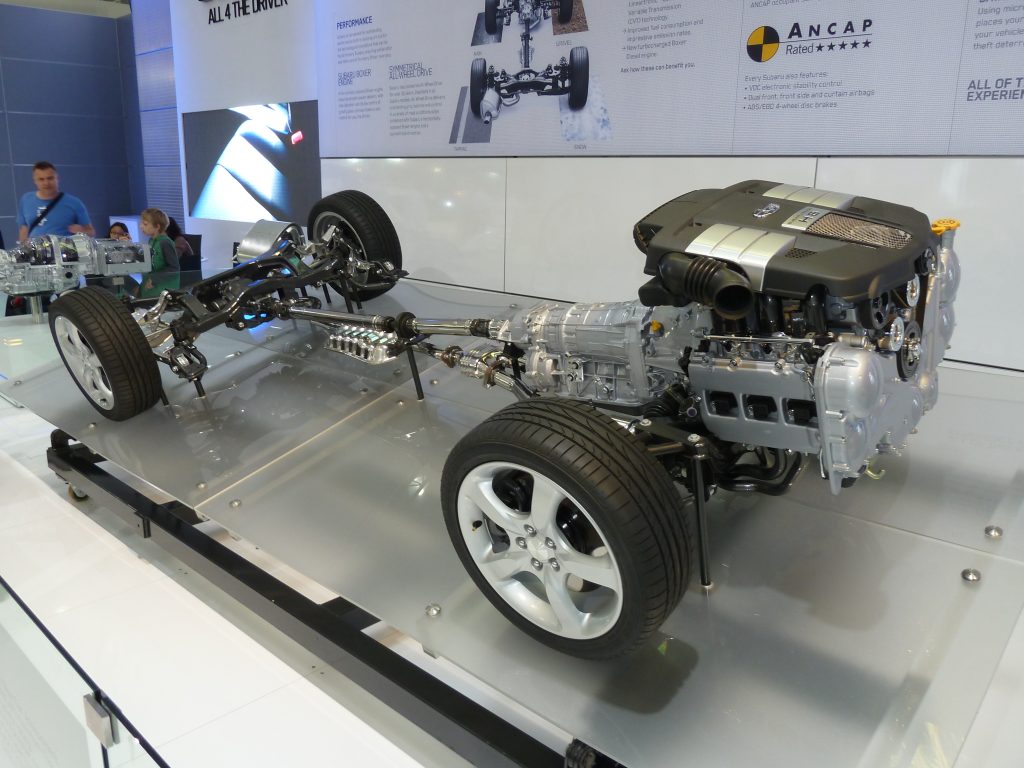

As the automotive sector accelerates the shift to electrification, induction heating has emerged as a critical technology in manufacturing advanced electric motors.

Simply applying induction heating isn’t enough. The real difference between success and failure—between flawless parts and rejected batches—comes down to custom coil design.

Induction heating drives compliance with NADCAP and AMS while boosting efficiency, traceability, and ROI for aerospace fastener manufacturers.

Induction heating has become a critical, highly efficient, and precise tool for a wide range of automotive manufacturing processes, enabling faster production, better quality, and lower environmental impact compared to traditional heating methods.

The ability to draw higher efficiency and precision from these tools has made automation essential in induction heating systems, enhancing operational control and providing adaptability far beyond what manual methods offer.

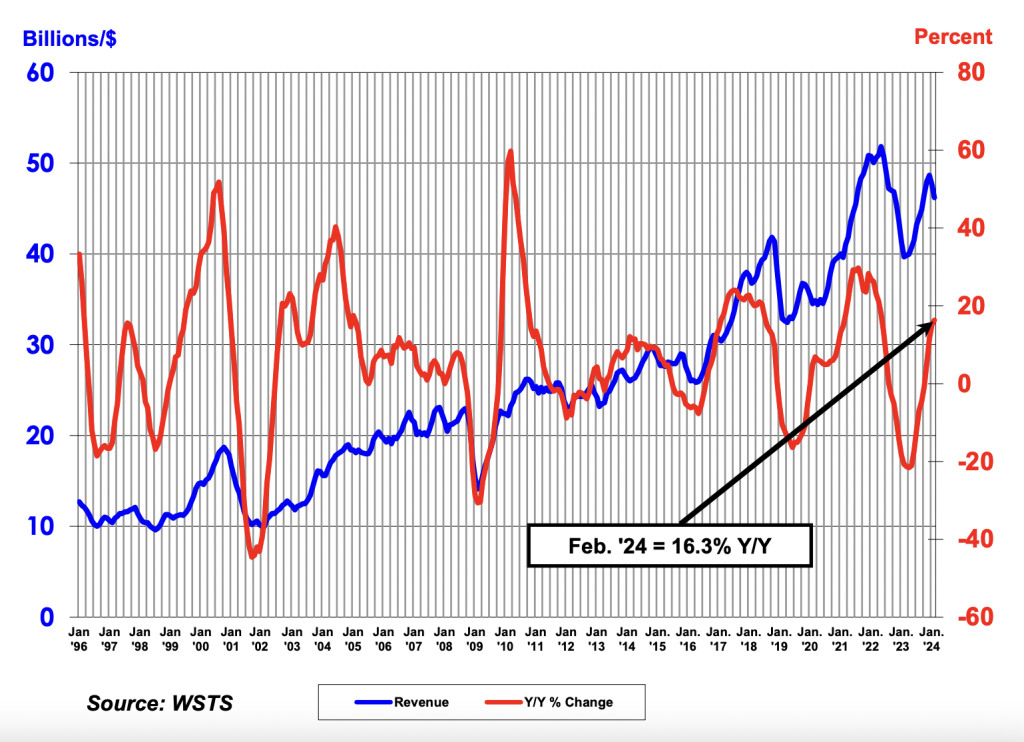

The Semiconductor Industry Association announced in early April that global semiconductor sales totaled $46.2 billion in February 2024. That’s an increase of 16.3% compared to the February 2023 total of $39.7 billion.

Qualified inspectors play a critical role in ensuring the quality and reliability of tin soldering jobs, especially when using induction heating or other methods.

Brazing and Soldering are both metal-joining processes that you’d encounter in manufacturing facilities of all stripes. The core difference lies in the temperature that this process demands, as well as the alloy utilized as a filler metal.

Let’s quickly define “annealing” in the context of metalwork and induction heating:

Annealing is a heat treatment process used to heat a material, like a metal or an alloy, to a specific temperature and then gradually cool it in a controlled manner.

Semiconductors play a pivotal role in the global economy. That may sound like a bold claim, but it’s a basic fact as we move further into the 21st century. Induction heating is a critical tool in semiconductor manufacturing.

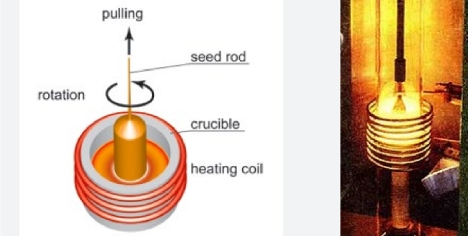

Silicon is the most widely used material in semiconductor manufacturing, and induction heating provides an efficient process for developing monocrystals (and, ultimately, semiconductor wafers).

Precision and control: These are the keys to welding in your facility. Induction heating equipment offers a good starting point.

Induction heating, harnessing the manipulation of electromagnetic fields, gives engineers and welders of all stripes an unprecedented degree of temperature precision, uniformity, and energy efficiency. This efficiency redounds to your entire manufacturing operation.

Hot heading can refer to a few different processes depending on the context, but it generally involves the shaping or forming of metal or other materials at an elevated temperature.

In metalworking, hot heading allows for metal to be pressed or forged into a specific shape using a die or a punch. This process is commonly used in the manufacture of fasteners, such as bolts and screws, where the heated metal is formed into the desired head shape.

Induction heating is a powerful tool in a manufacturer’s arsenal. Depending on the job, this technology is a cost-effective method for heating metal or other materials and developing specific end products at scale.

In every manufacturing or industrial engineering business, energy efficiency is a critical variable for understanding how successful your operation may be in the broader marketplace.

This is one reason why induction heating equipment is on the rise in manufacturing facilities across the globe.

If your team needs to selectively enhance or restrict inductive properties in a certain area of the material you’re heating, then you’re looking for a patch coating solution.

Patch coating is a process where a specific area of a metal part is coated with a material that changes its electromagnetic or thermal properties.

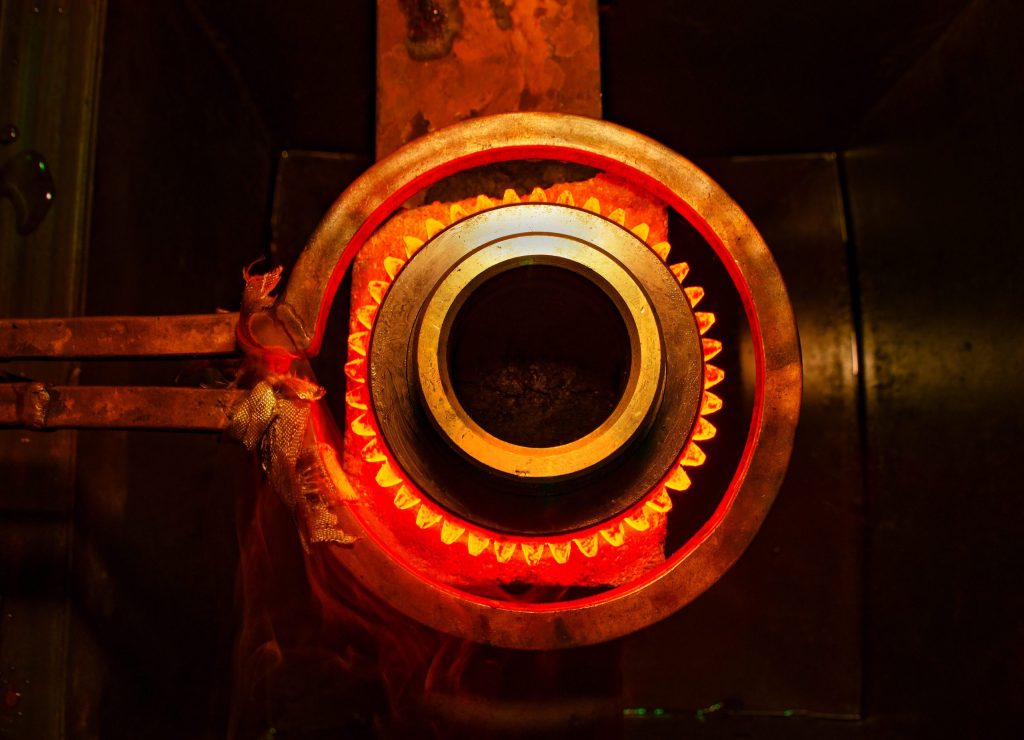

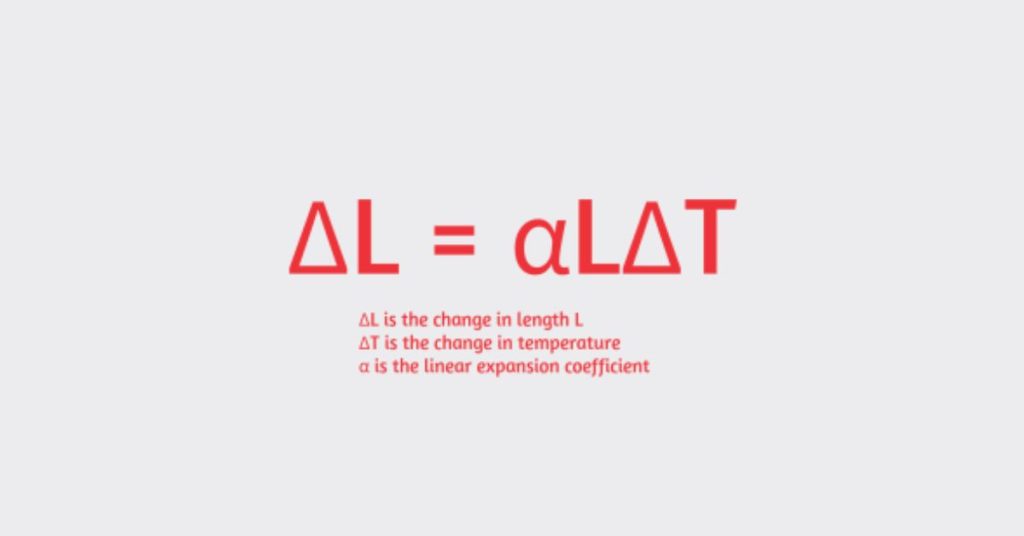

Let’s say your manufacturing operation must fasten a metal gear to a metal shaft, creating a durable connection. The gear has an inner diameter, of course, and the shaft has an outer diameter.

Welding won’t get the job done, so, instead, your team turns to shrink fitting and induction heating.

In manufacturing settings, the curing process is pivotal in determining the final properties of materials, ensuring that the finished product will be able to withstand the stresses and strains it will be subjected to in its intended use.

Induction heating offers an efficient medium for getting your work done at scale.