Chillers

Home » Chillers

- Chillers

Reliability and Efficiency

Heating Induction Chillers are designed for industrial use and for installation in an external environment. A broad range of options available in product configuration and accessories in kit form, complete the already generous standard equipment and allow this machine to meet most requirements of industrial applications.

Heating Technology Source offers a range of chillers, including air-cooled and water-cooled chillers. These chillers are designed to meet the specific needs of customers and are made of high-quality materials to ensure reliability and efficiency.

Therefore Induction Heating Chillers offered by Heating Technology is therefore the chilling solution for all applications that require high performance, reliability, continuity of operation and reduced management costs.

Heating Technology Chilling Solutions Product Brands

MTA Chilling Solutions

For over 35 years, MTA has manufactured process cooling solutions designed to perform in tough manufacturing environments

Thermal Care Chilling Solutions

Since 1969, Thermal Care has manufactured industrial water chillers and process cooling equipment for industry worldwide.

- ARIES TECH 2

- TAEevo Tech

- TAEevo TECH Mini

- Accuchiller EQ Series

- Accuchiller NQ Series

- Accuchiller KSE Series

- FC Series – Cooling Tower

- FT Series – Cooling Tower

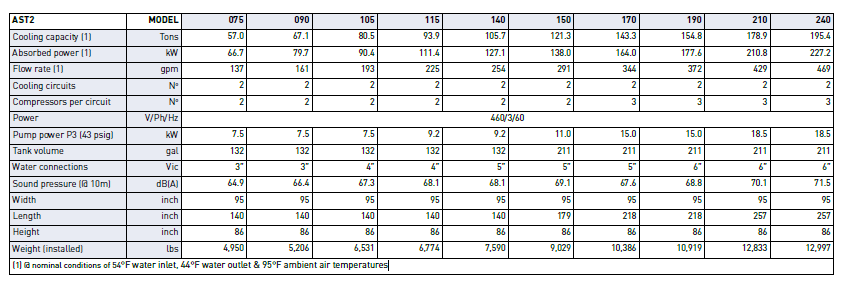

ARIES TECH 2

ARIES TECH 2

AIR-COOLED INDUSTRIAL CHILLERS WITH SCROLL COMPRESSORS – R410A

NOMINAL COOLING CAPACITY 57-195 TON

The ARIES TECH 2 is an industrial-grade chiller that combines MTA’s reliable packaged refrigeration with on-board coolant pumping & storage to provide single point cooling solutions up to 195 Tons. A full range of sizes and options makes ARIES TECH 2 the right fit for any application, and built-in capability for modularity allows these chillers to grow with increasing process cooling demands.

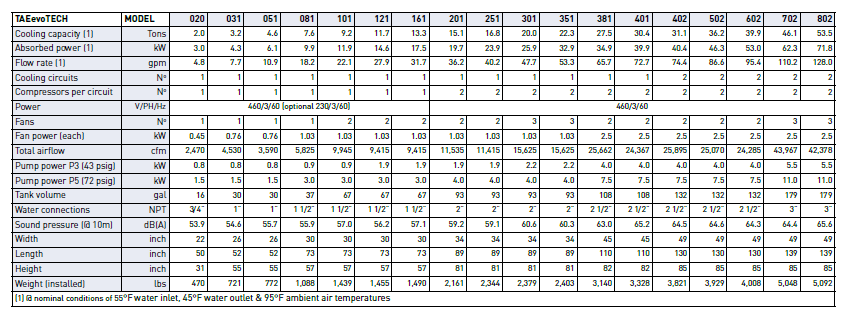

TAEevo Tech

TAEevo Tech

AIR-COOLED INDUSTRIAL CHILLERS WITH SCROLL COMPRESSORS – R410A

NOMINAL COOLING CAPACITY 2-53 TON

TAEevo Tech is an air-cooled liquid chiller, designed for industrial use and for installation in an external environment. A broad range of options available in product configuration and accessories in kit form, complete the already generous standard equipment and allow this machine to meet most of the requirements of industrial applications. TAEevo Tech is therefore the solution for all applications that require high performance, reliability, continuity of operation and reduced management costs.

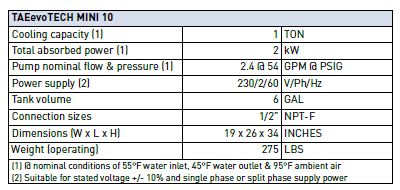

TAEevo TECH Mini

TAEevo TECH Mini

New generation of compact liquid chillers for industrial processes. Most of the industrial processes today have a growing need for competitive technical solutions suitable to ensure greater productivity, meeting the high-quality requirements of the final product and being environmentally friendly. The reliability, the compactness and flexibility of the cooling systems significantly reduce the operating costs and the environmental impact of the entire plant. The new generation of liquid chillers TAEevo Tech MINI has been specifically designed for processing cooling water and antifreeze mixtures, ensuring superior reliability, minimum dimensions, and high energy efficiency.

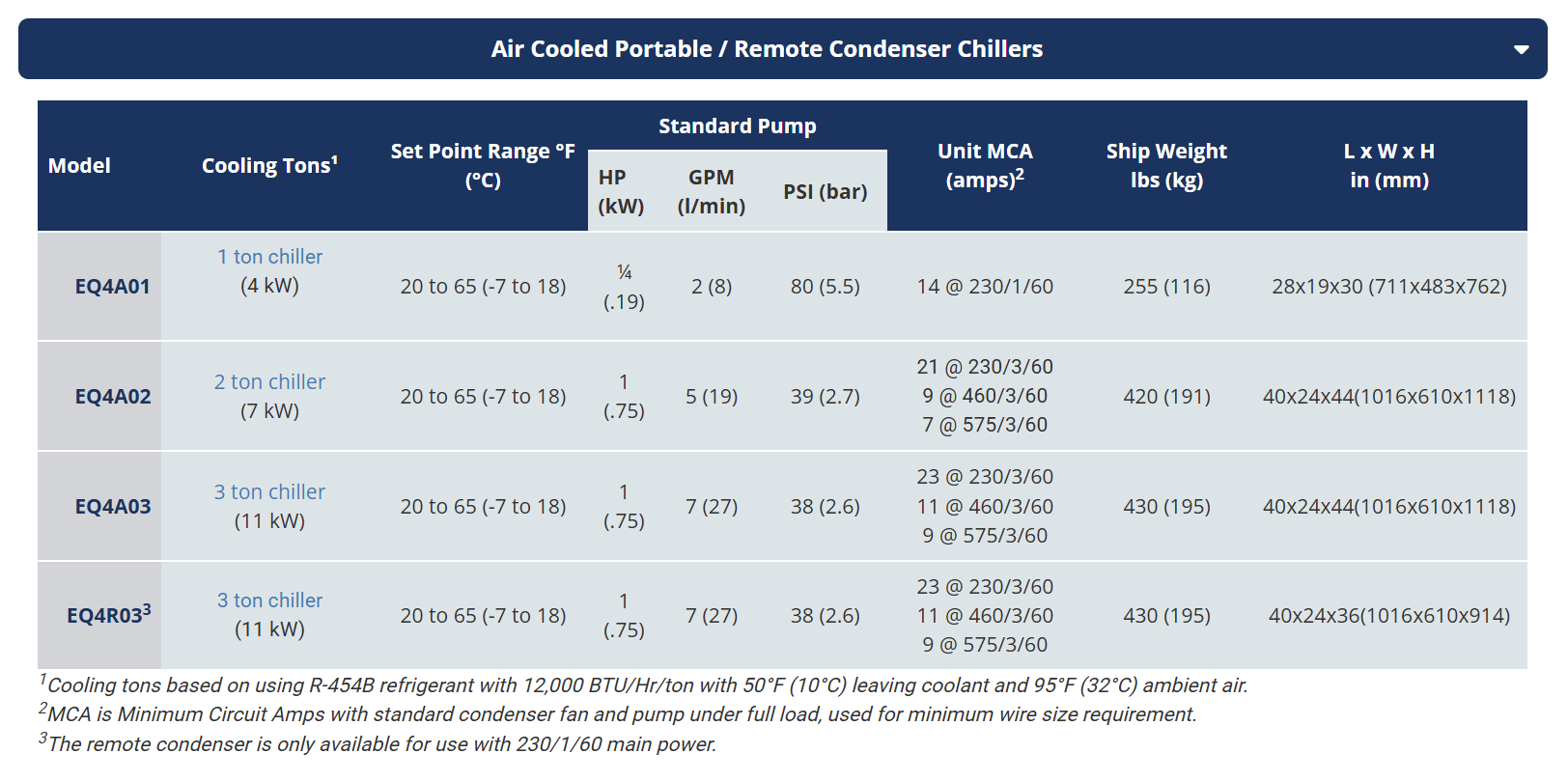

Accuchiller EQ Series

Accuchiller EQ Series

Accuchiller EQ Series portable industrial chillers feature a compact footprint with an easily accessible interior and a PLC controller that provides precise temperature control and extensive diagnostics. Air-cooled, water-cooled and remote condenser models are packed with many standard innovative features that improve chiller performance and reliability.

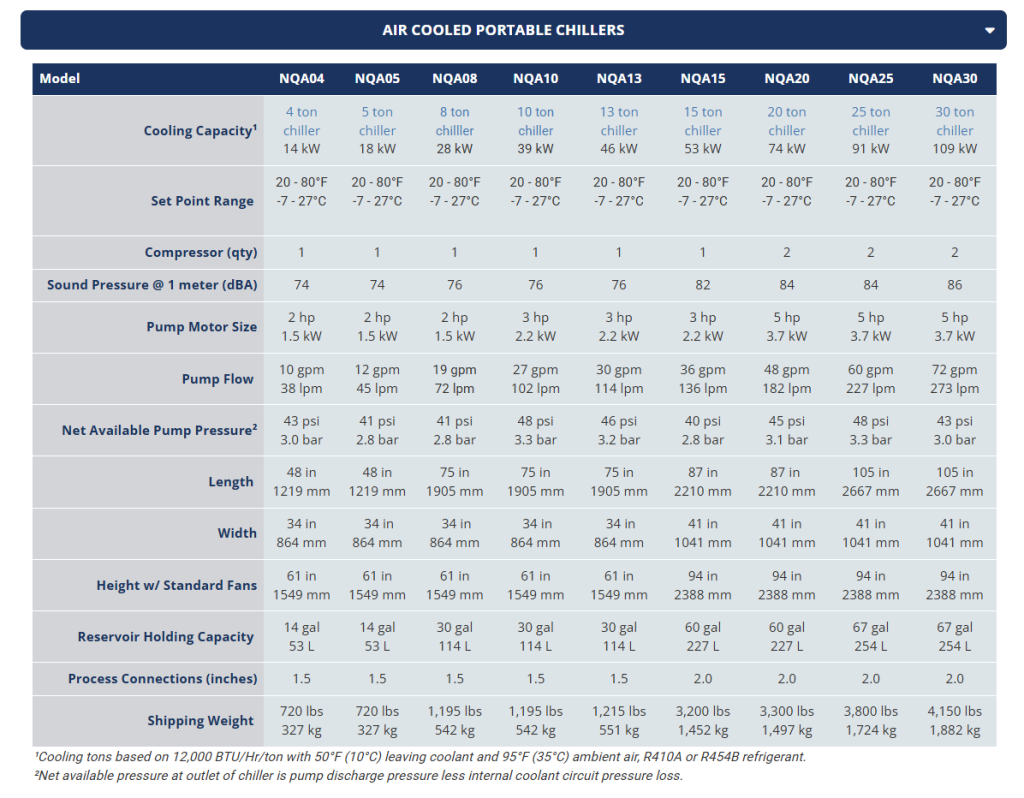

Accuchiller NQ Series

Accuchiller NQ Series

NQ Series industrial portable chillers use components such as scroll compressors, microchannel condensers, low noise fans, stainless steel brazed plate evaporators, and NQ Series PLC controls with large color touch screens to provide the best available technologies for the ultimate performance and reliability in a chiller package.

FT Series Cooling Tower

FT Series Cooling Tower

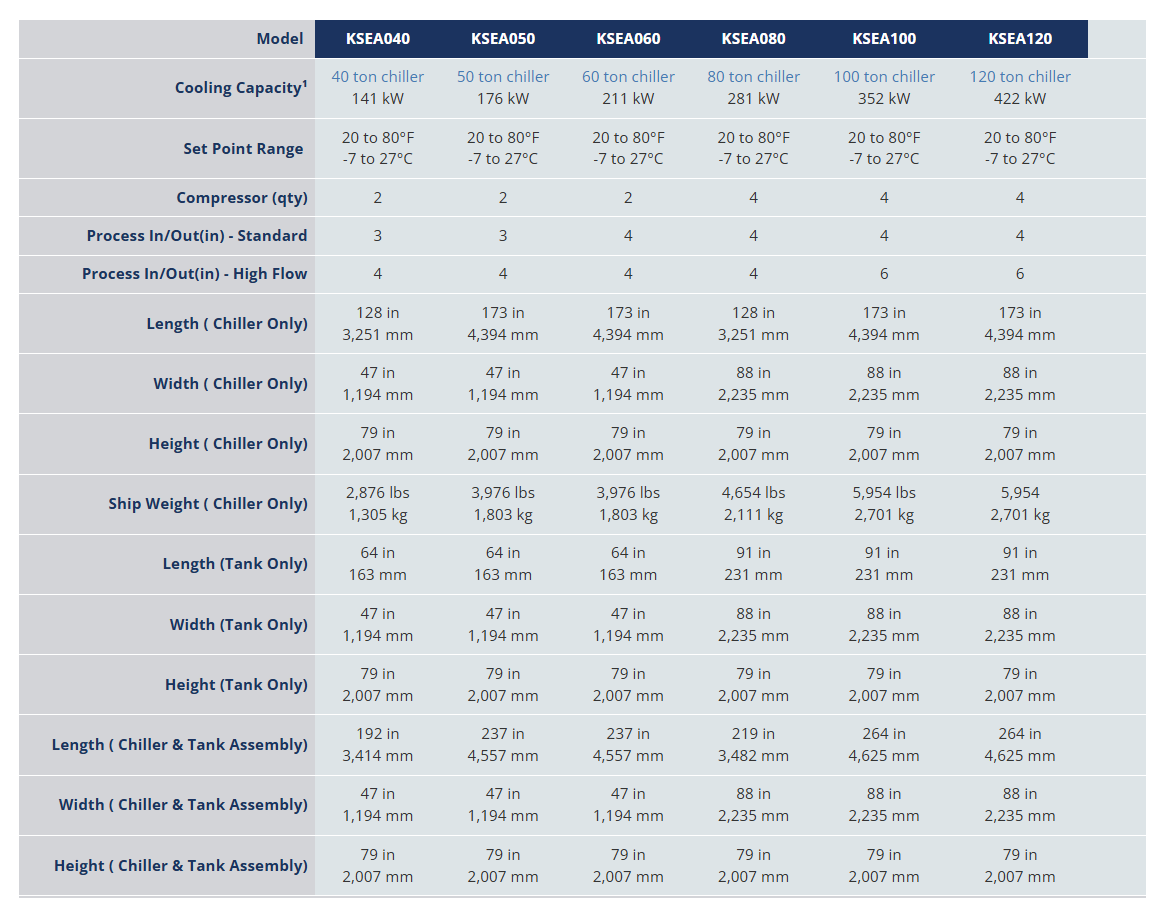

KSE Series industrial outdoor air-cooled chillers feature a compact, all-in-one package designed to minimize installation cost, maximize usable space and lower electric bills. Designed for harsh outdoor environments KSE Series chillers require no options to operate within the standard -20°F to 125°F (-29°C to 52°C) ambient environment conditions. Standard process fluid temperatures of 20°F to 80°F (-7°C to 27°C) are ideal for industrial applications. The modular design allows up to 12 refrigeration circuits to be combined into a single system for up to 720 tons (2,532 kW) of cooling capacity.

FC Series Cooling Tower

FC Series Cooling Tower

Thermal Care provides durable, efficient and low-maintenance cooling towers designed for premium quality and performance. Key features include a seamless, leak proof basin and a motor with permanently sealed bearings ensuring long-term reliability. Each tower features fiberglass construction of the shell and basin for long life and corrosion resistance.

Industrial cooling towers are an effective way to remove unwanted heat from one place to another using water as the transport media. Cooling towers are an extremely cost-effective solution for process cooling when the temperature required is near 85°F (29°C) or above. Water-cooled chiller condensers also typically require 85°F (29°C) inlet water, so a cooling tower system is perfect for a water-cooled chiller system.

FT Series Cooling Tower

FT Series Cooling Tower

Thermal Care provides durable, efficient, and low- maintenance cooling towers designed for premium quality and performance at a competitive price.

FT Series towers feature a counterflow design, carefully engineered with the optimum combination of heat transfer media, uniform airflow and balanced water distribution. This provides maximum air/water contact and low air pressure drop to assure efficient heat transfer while minimizing power requirements to save on operating costs. Each tower features fiberglass construction of the shell and basin for long life and corrosion resistance.

Industrial cooling towers are an effective way to remove unwanted heat from one place to another using water as the transport media. Cooling towers are an extremely cost-effective solution for process cooling when the temperature required is near 85°F (29°C) or above. Water-cooled chiller condensers also typically require 85°F (29°C) inlet water, so a cooling tower system is perfect for a water-cooled chiller system.